WHO PRODUCES LITHIUM ION BATTERIES SOFTWARE

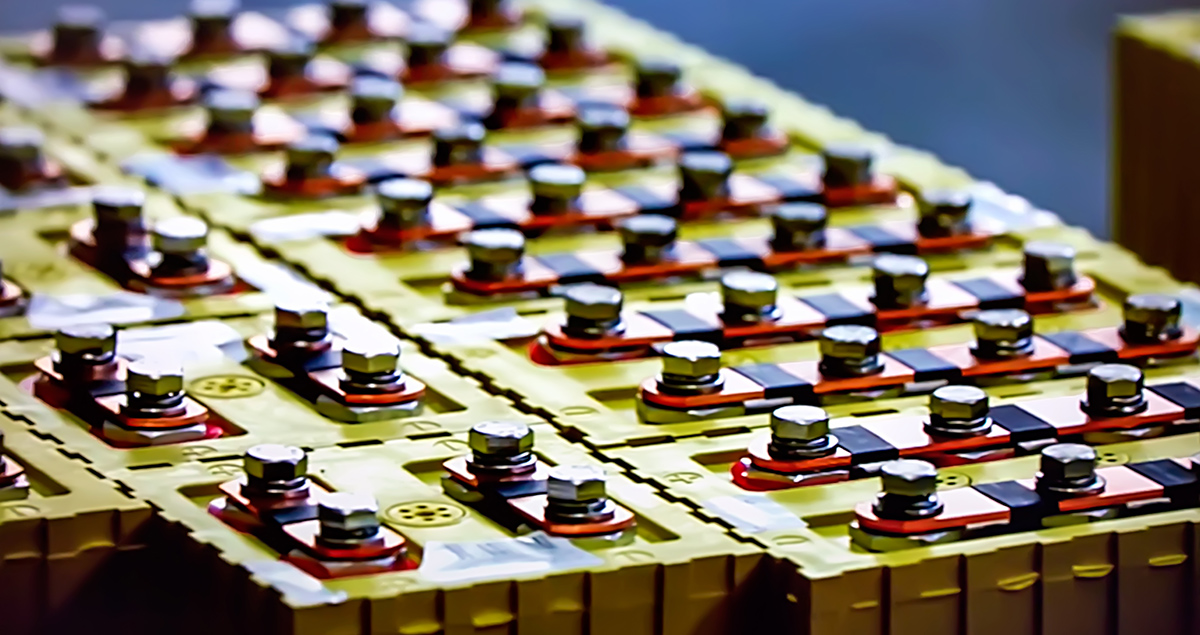

The subassemblies-such as for example the “technology container,” which houses software peripherals and supplies the battery with the “brainpower” it requires for intelligent charging-are also produced here. In the production section, the lithium-ion cells and numerous other components are assembled and wired together to make a powerful battery system. At present, no fewer than 80 employees work in production, and in research and development, at the KION battery plant in Karlstein am Main. The configurations for the batteries are consequently also extremely varied, which means that in fact we currently place greater value on high-quality craftsmanship than on large-scale automated processes,” explains Carsten Harnisch, Vice President New Energy Systems at KION and Managing Director of KION Battery Systems GmbH (KBS). “We manufacture batteries here for an extremely broad range of trucks. But spending rules need to be streamlined so that building a battery plant does not take the same amount of time as a coal plant.A vast hall, bright strip lights, high shelving, a variety of conveyor belts, and in between these: staff busily engaged in all kinds of tasks, using a range of tools to work on an equally diverse range of battery components. A European Sovereignty Fund would support a truly European industrial strategy and not just countries with deep pockets. Julia Poliscanova said: “Europe needs the financial firepower to support its green industries in the global race with America and China.

EU state aid rules also need to be streamlined so that green projects can be scaled up using production aid – as is already permitted in the US. Spending under the RRF also lacks strategic focus, funds are often slow to reach companies, and the money is not bankable in the same way as the US IRA production credits. Only green production targeted by the US IRA, such as electric vehicles, batteries, and renewables, should receive cash.īut, unlike Next Generation EU, the funds should be disbursed directly by the EU to companies to avoid the slow absorption rates seen under the Recovery and Resilience Facility (RRF). This would provide a level European playing field and avoid cash-rich countries leaving others behind by offering generous state aid to companies. But the Inflation Reduction Act has changed the rules of the game, and Europe needs to put more money on the table or risk losing planned battery factories and jobs to America.”Ī European Sovereignty Fund to support green technologies should be established with cash raised through joint debt issuance, T&E said. Today half of the lithium-ion battery cells used in the EU are already made there. Julia Poliscanova, senior director for vehicles and e-mobility at T&E, said: “The EU’s phase-out of combustion engines in 2035 has already spurred much investment. The materials will be sourced from mines abroad or directly from European projects under a planned EU Critical Raw Materials Act provided they meet high environmental standards. These include RockTech Lithium and Vulcan Energy Resources in Germany, and Imerys in France. Reliance on China for the refining and processing of battery metals could also fall dramatically: more than 50% of Europe’s refined lithium demand can come from European projects by 2030, T&E forecasts. But companies could still move projects planned for Europe to the US, tempted by the tax benefits and other subsidies provided by the Inflation Reduction Act for localising battery supply chains in America. Existing and planned cathode production projects include Umicore in Poland, Northvolt in Sweden, and BASF in Germany. Two-thirds of Europe’s demand for cathodes – which contain critical raw materials – can be produced domestically by 2027, the report also finds. However, the green group said the EU needs a policy to counter US subsidies or risk losing investments in the EV supply chain.Ĭhina’s dominance of battery components can also be cut. Europe is on track to produce enough Li-ion cells by then to fully meet domestic demand for electric vehicles and energy storage, according to the new analysis of battery-makers’ announcements. The EU can end its reliance on China for lithium-ion battery cells by 2027, Transport & Environment (T&E) has forecast.

0 kommentar(er)

0 kommentar(er)